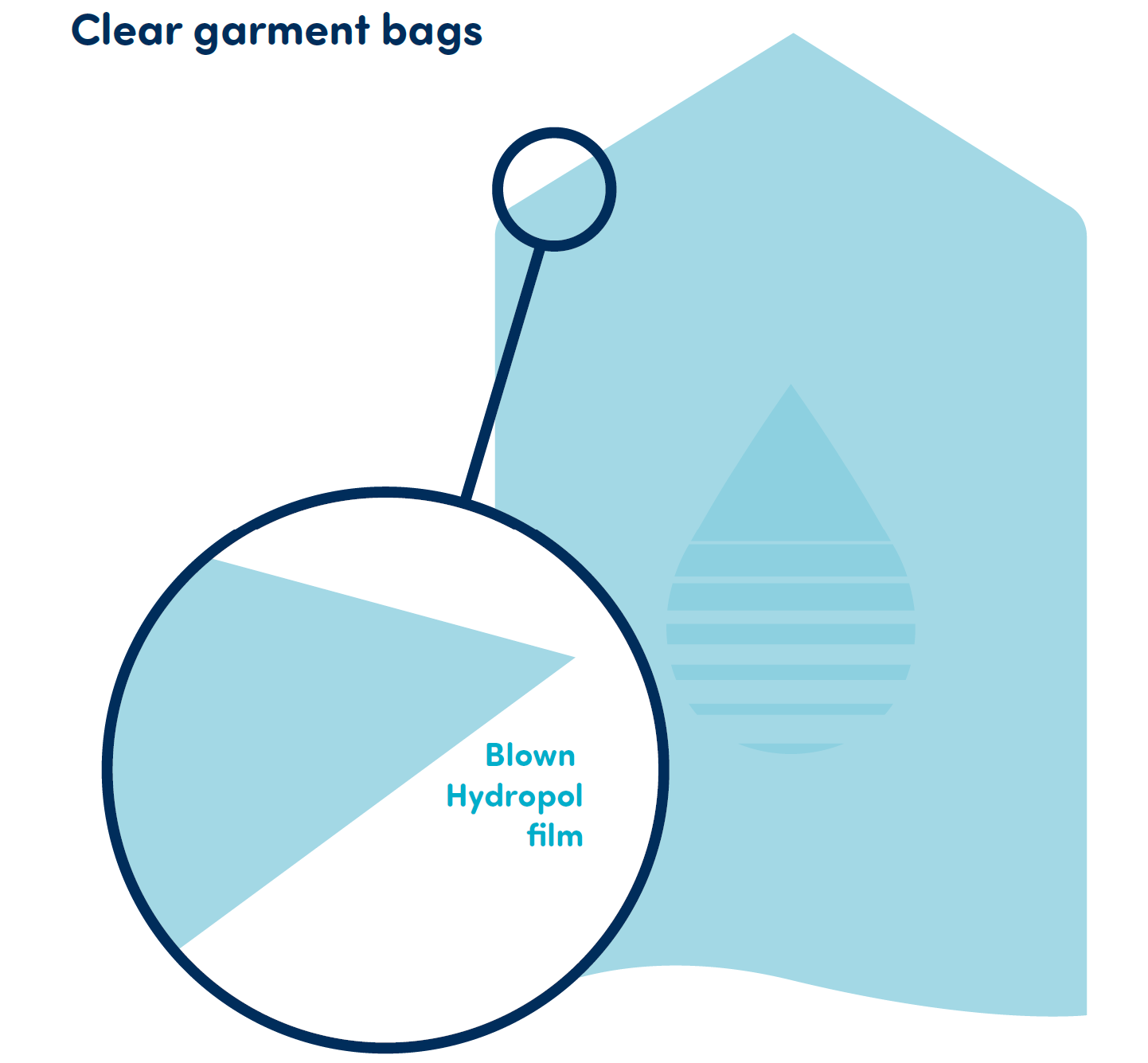

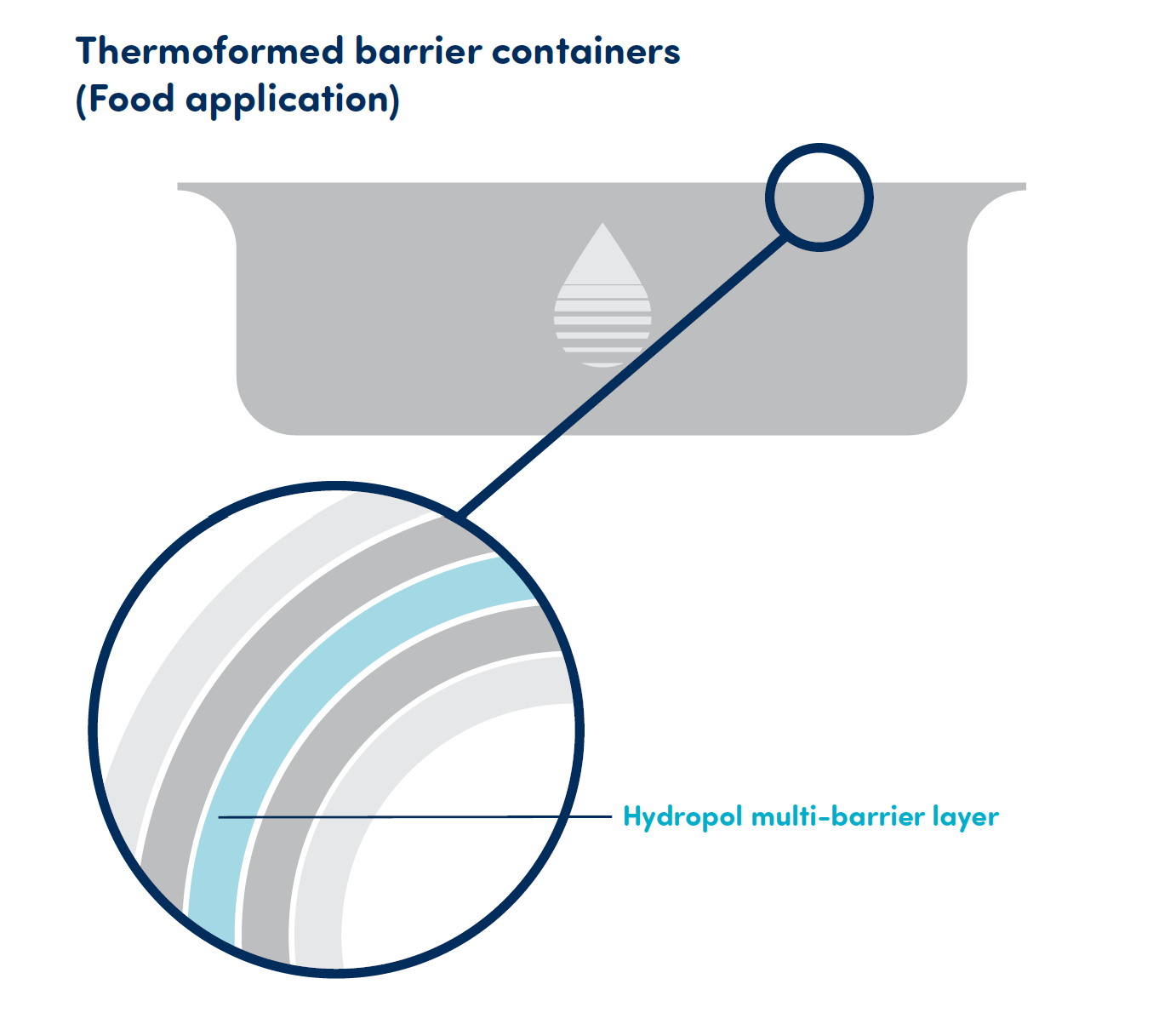

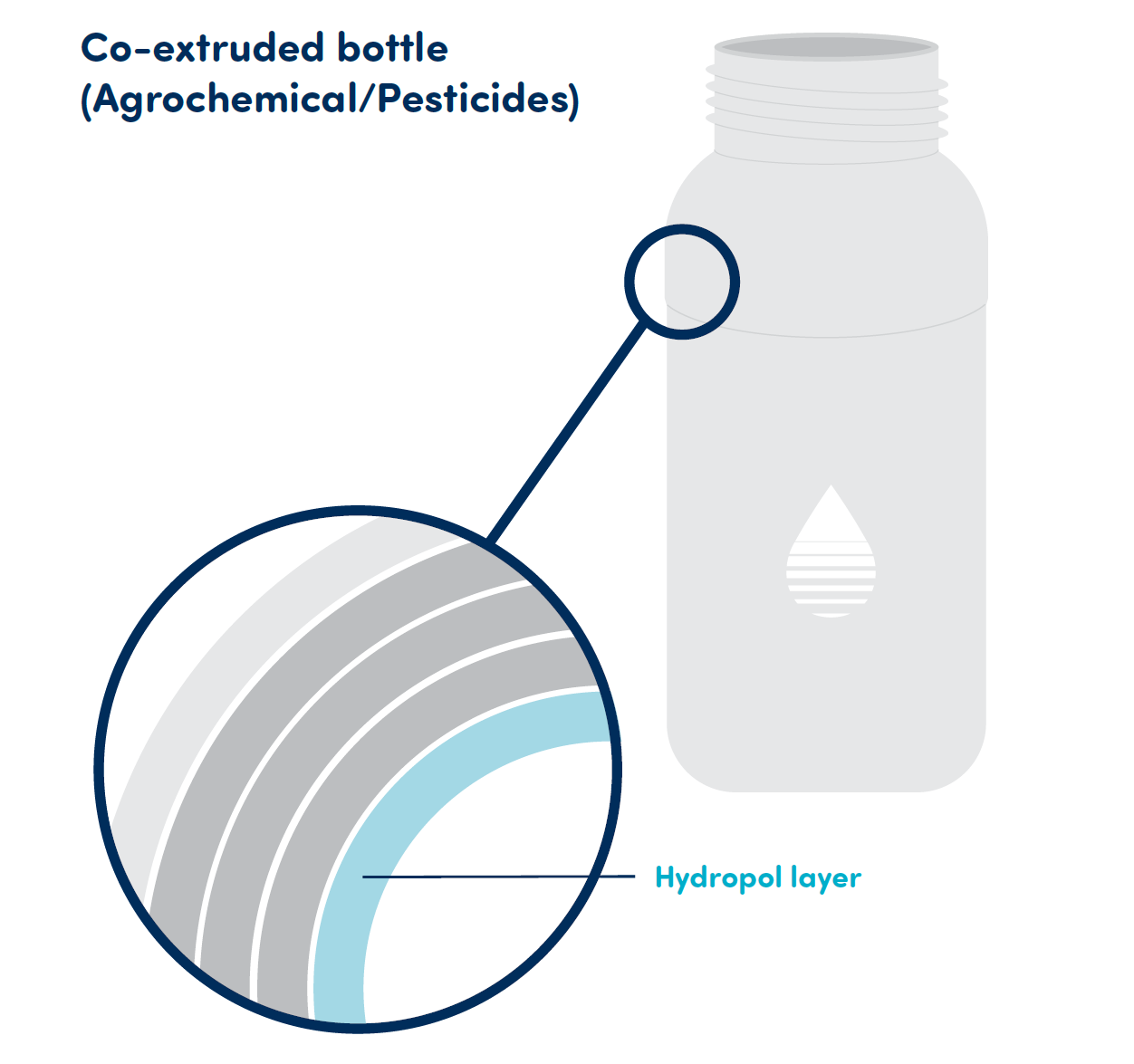

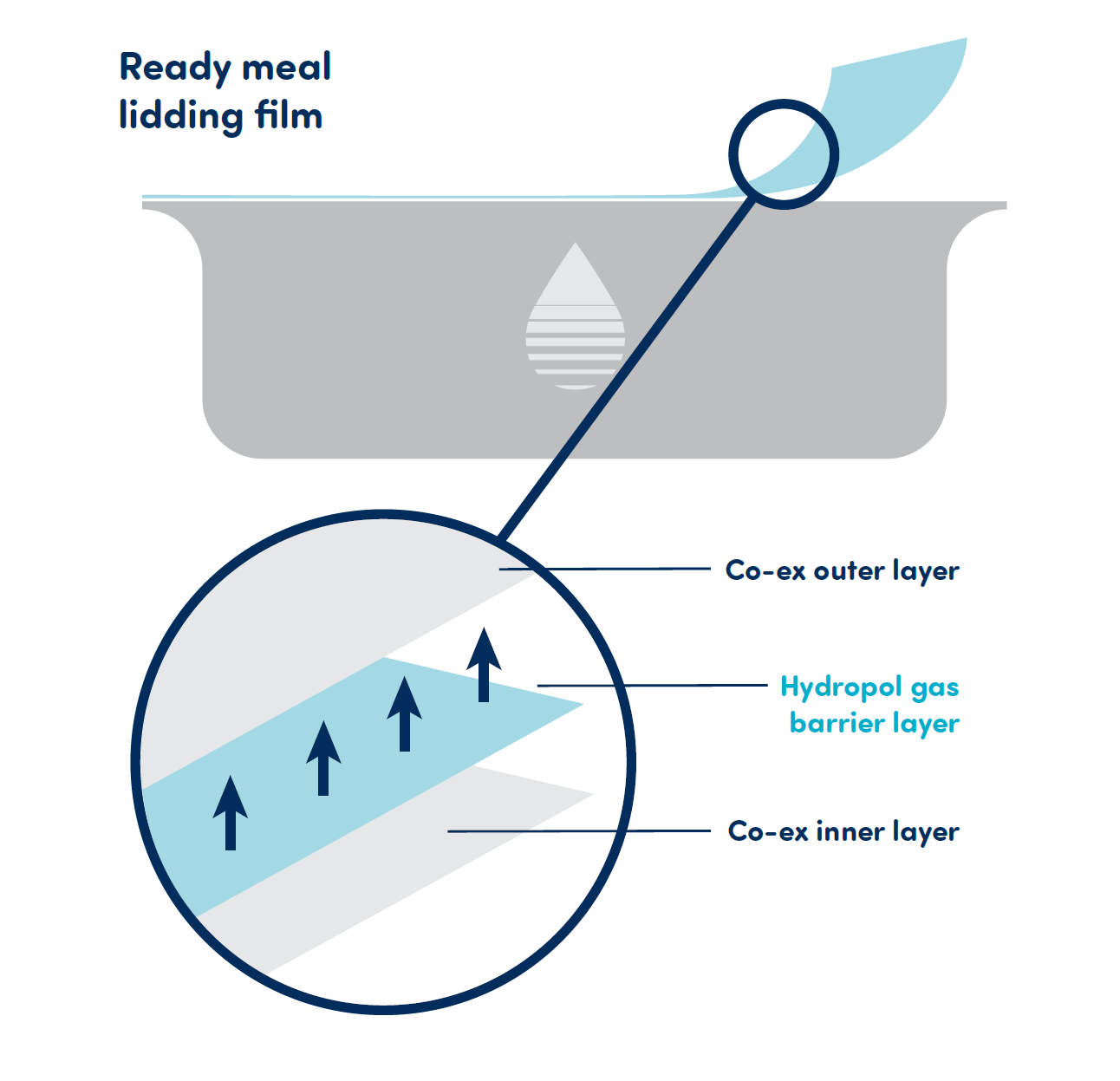

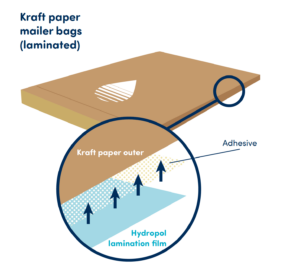

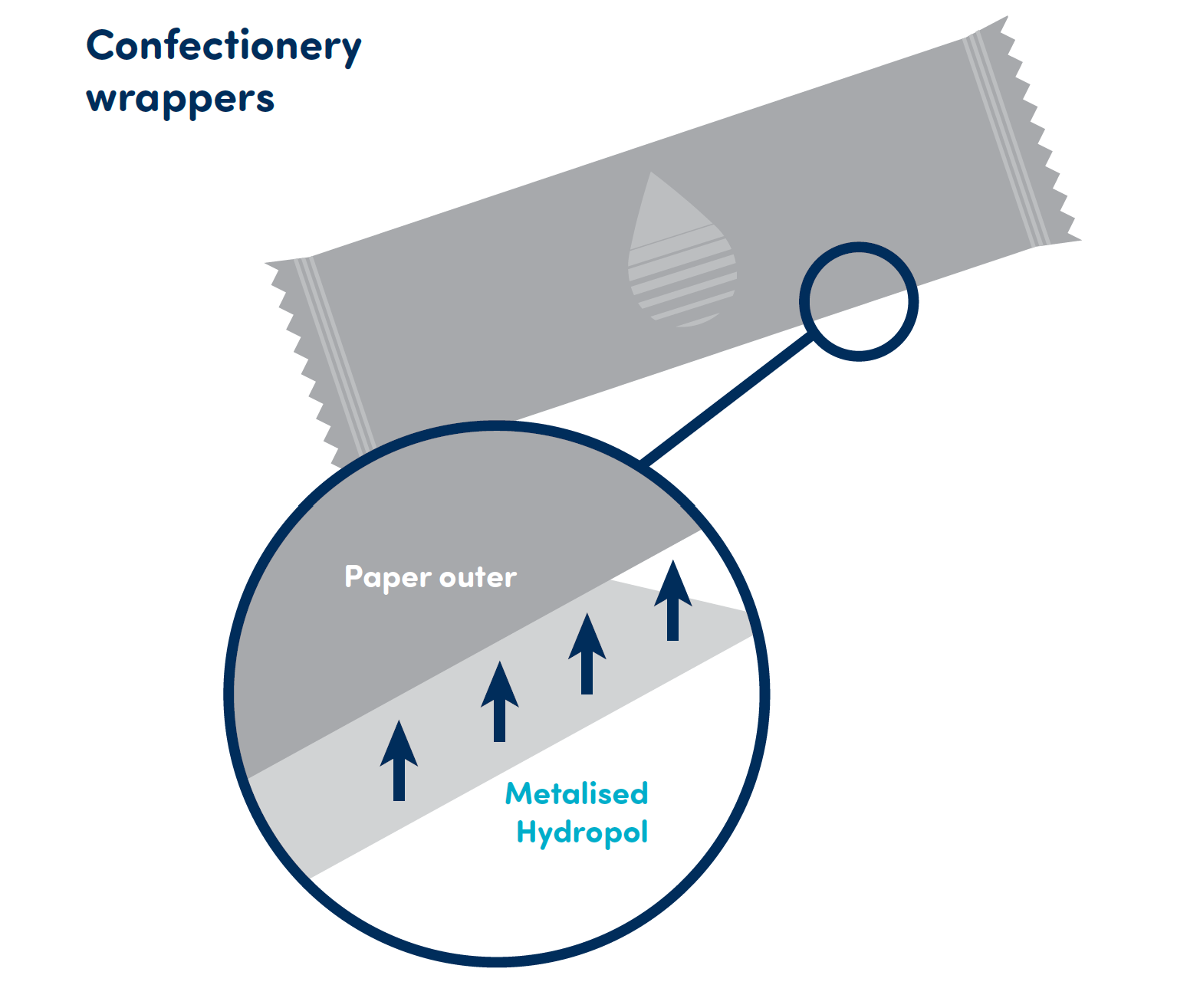

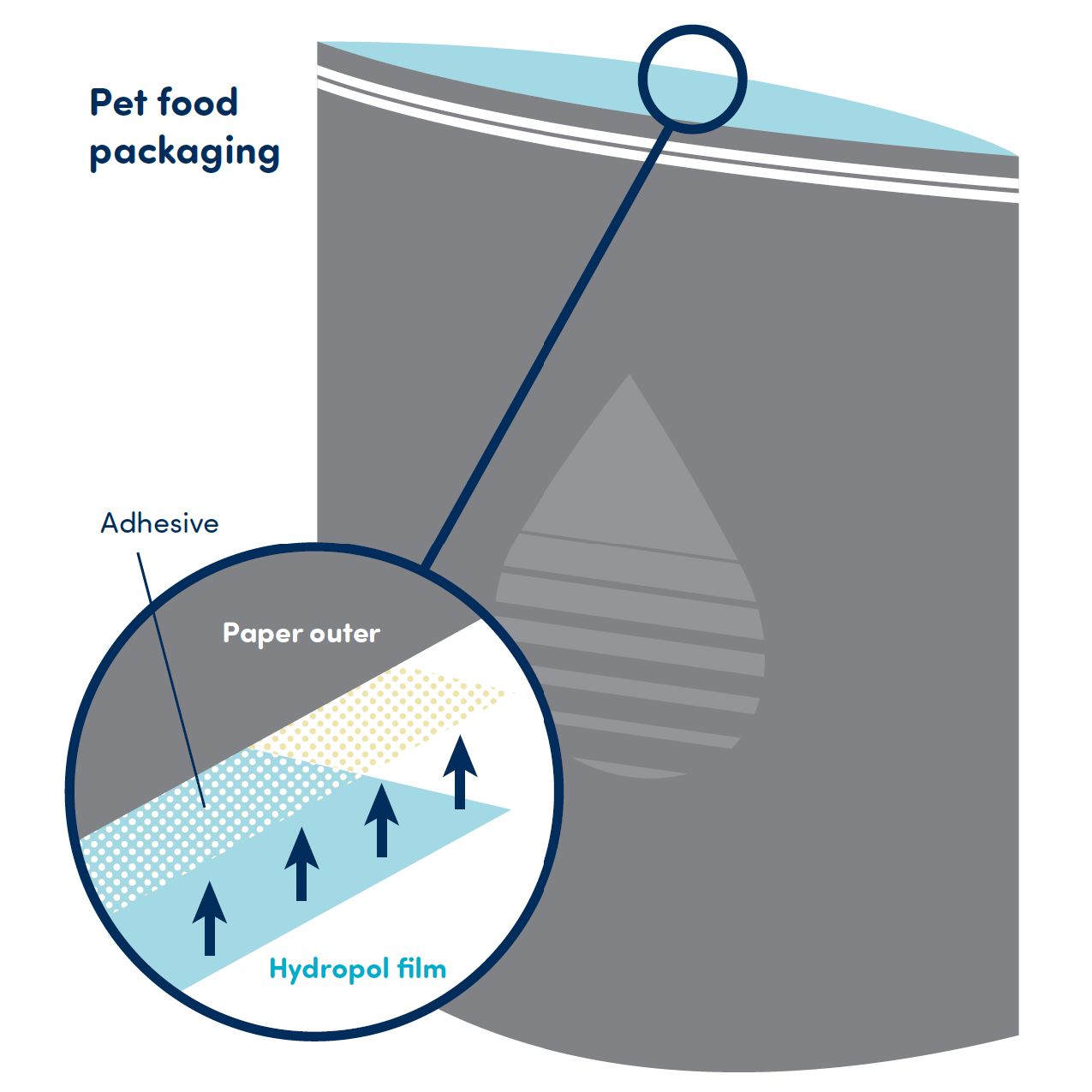

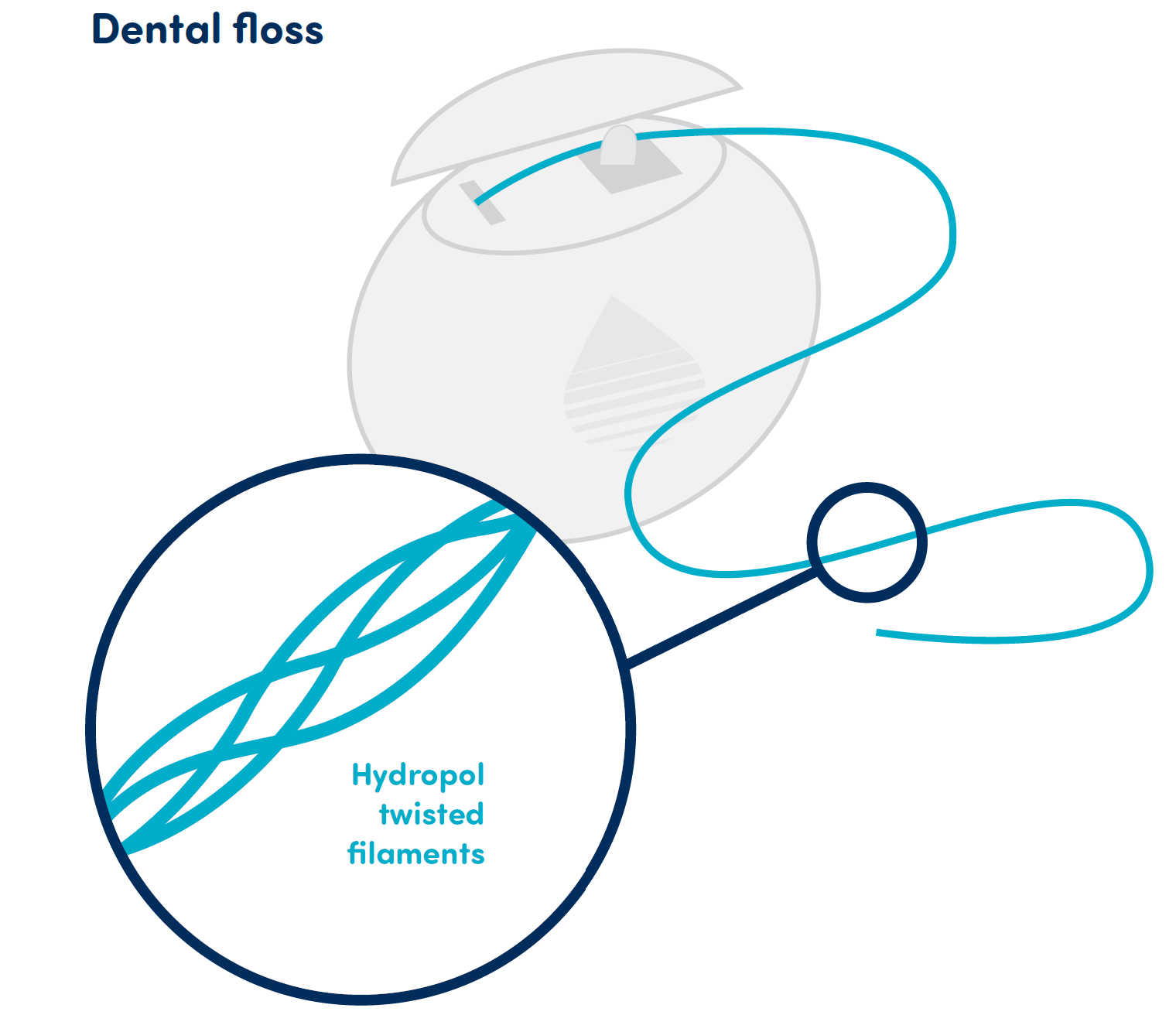

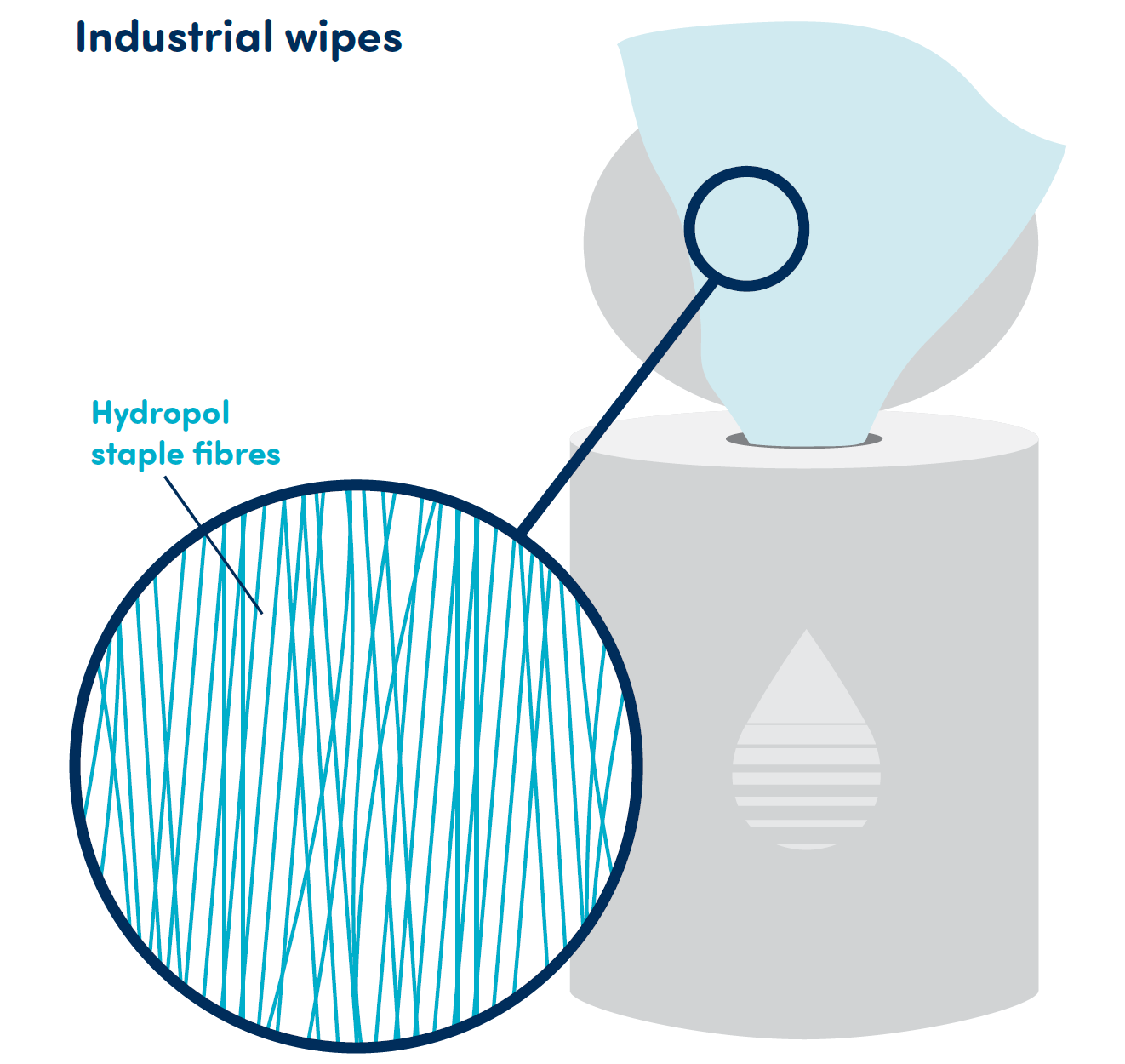

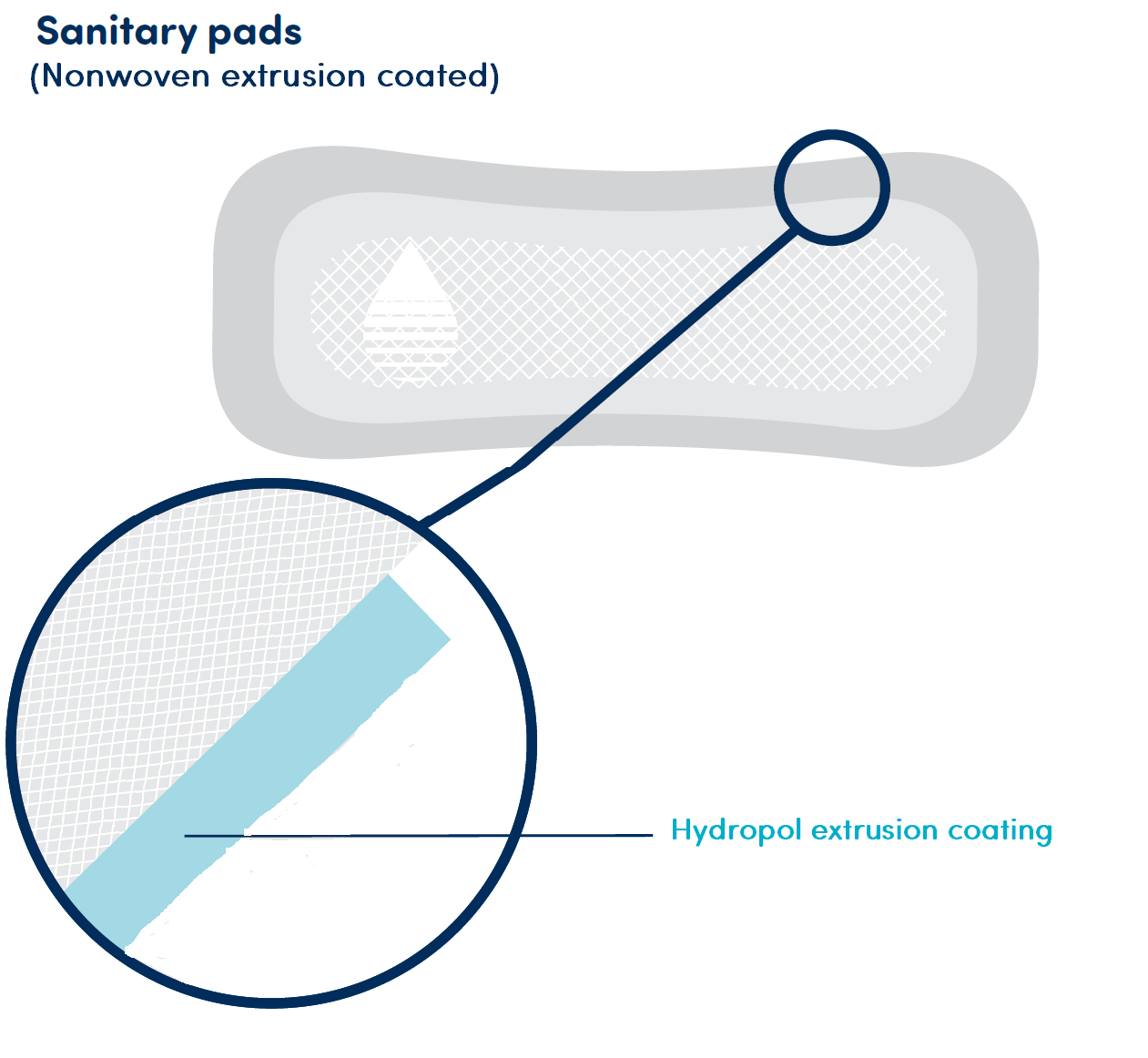

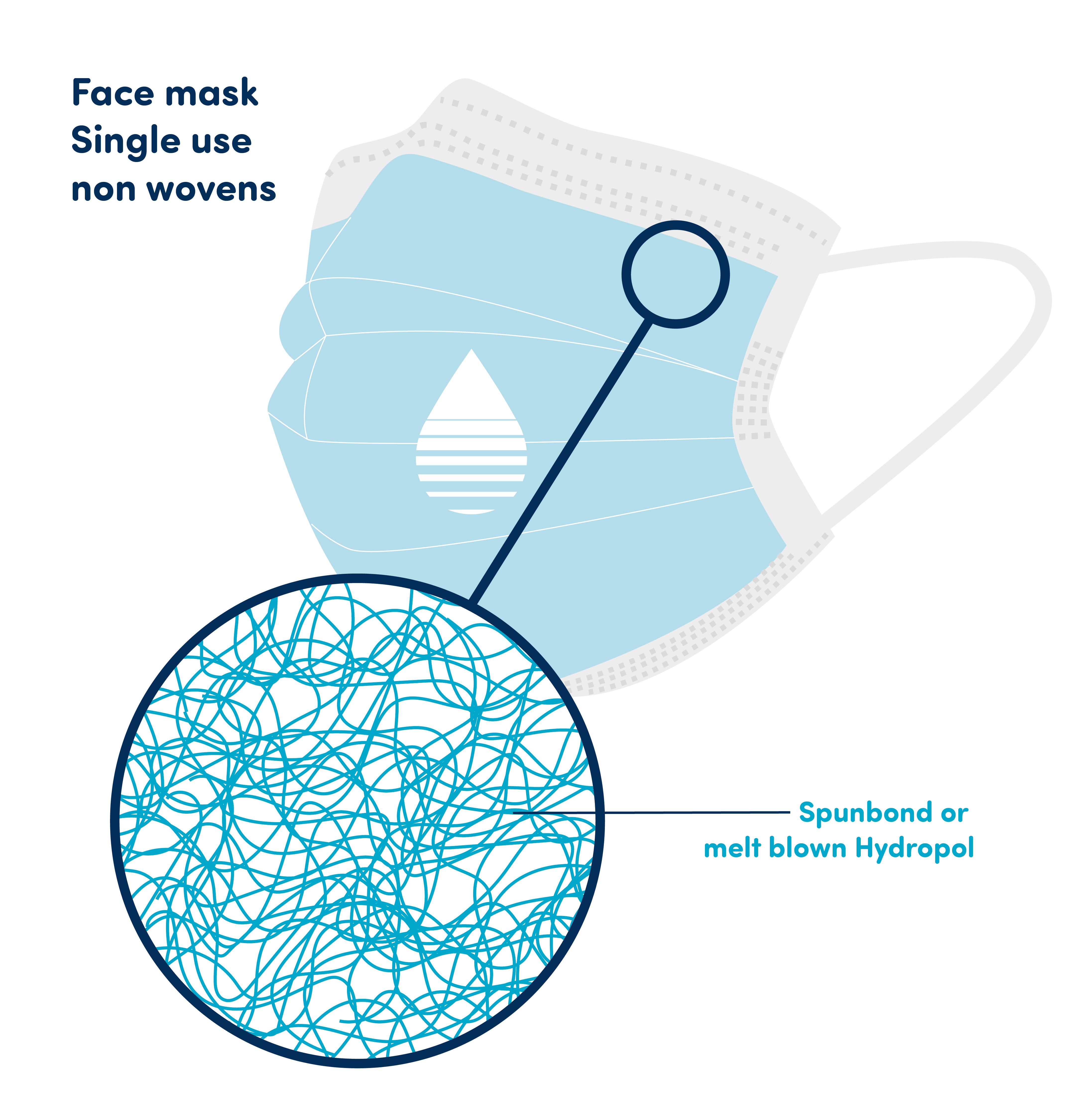

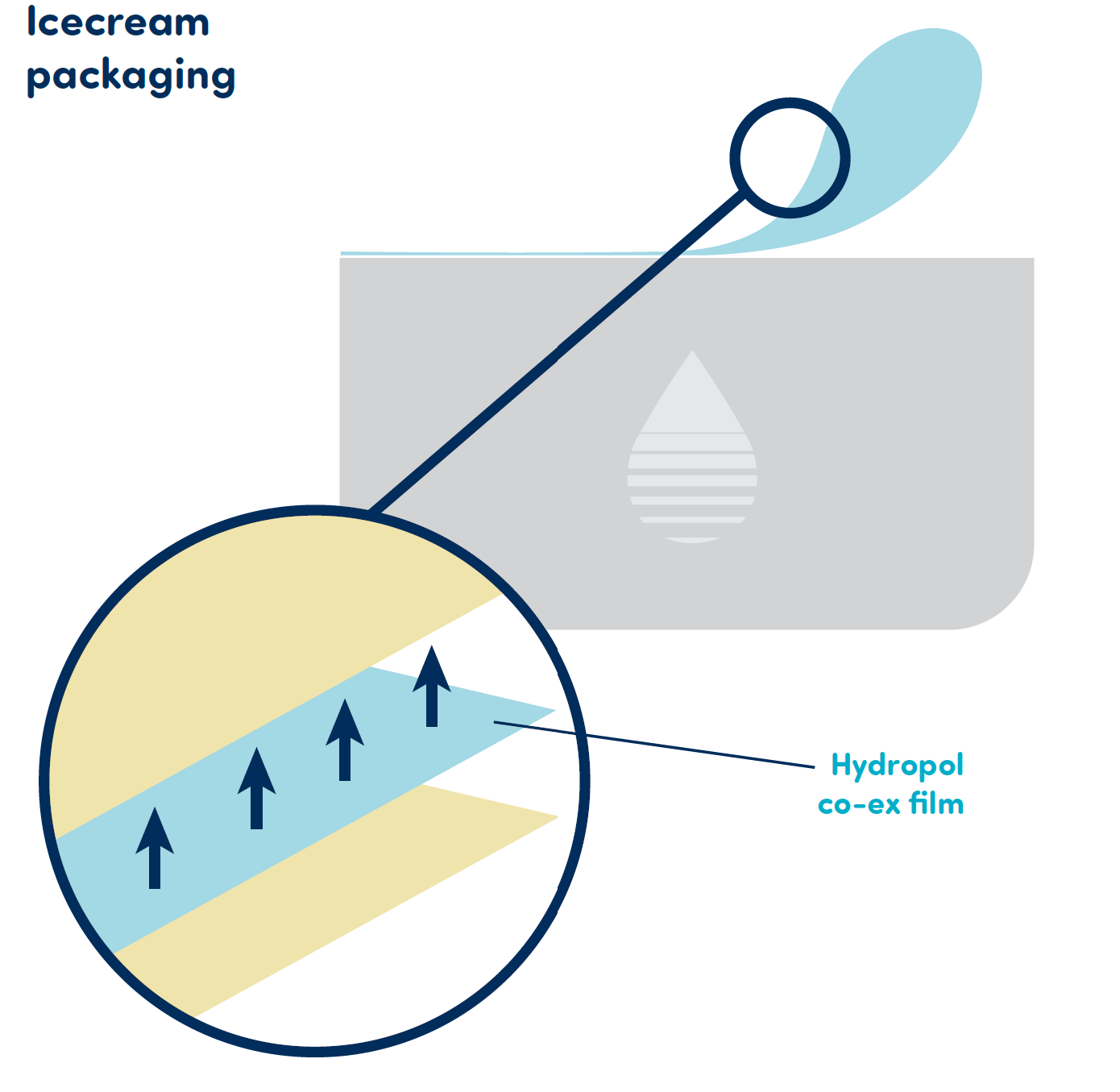

Hydropol™ Enables Diverse Applications

Hydropol provides key material properties that improve the functionality of end products and enables multiple end-of-life options. Aquapak’s patent-protected technology allows Hydropol’s use in standard thermo processing equipment.