Hydropol™ is a newly developed patent-protected material developed by Aquapak that is based on the water-soluble polymer PVOH (polyvinyl alcohol).

PVOH has been used for years as a simple soluble film layer in many applications. Most commonly you’ll find it in detergent tablets, pharmaceuticals and medical care.

It is widely recognised as being non-toxic and is hydrophilic which means it loves water and in comparison with conventional plastic has a positive end-of-life breaking down quickly and harmlessly into water, CO2 and biomass.

However, these water loving properties have also made it difficult to process on existing packaging machinery and so the scope of PVOH for other packaging applications has been limited. Until now.

How is Hydropol™ Different?

Over a 10-year R&D process Aquapak developed a new chemical formulation that stabilises and retains the positive end-of-life properties of PVOH, while enhancing functionality and crucially allowing thermal processing on existing packaging lines.

This opens up a much wider range of packaging applications. Unlike traditional PVOH, Hydropol™ can be combined with paper, made into barrier films, or used in nonwoven materials.

Environmentally Safe End-of-Life

Enhanced functionality & performance

Thermal processing on existing packaging lines

Enhanced Functionality & Processability

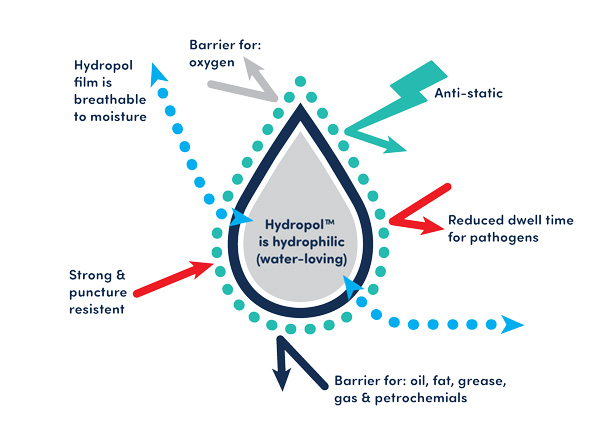

Hundreds of different chemicals were screened and tested to identify which could be safely combined with PVOH in a unique formulation that provides;

- Tailored water solubility

- Very high barrier to oxygen/oil/grease/gases/solvents

- Tensile strength and puncture resistance

- Biodegradability

- Zero harmful microplastics

Simple integration with existing packaging process.

HydropolTM also needed to be compatible with existing material/packaging production infrastructure to ensure it is easily adopted by the current supply chain. This makes it both scalable and commercially viable in the short and long term.

HydropolTM can replace conventional plastic (e.g. Polypropylene (PP) / Polyethylene (PE)) in many packaging applications, providing the same or enhanced performance and packaging functionality including;

- Heat sealable

- Printable without pre-treatment

- Stable and storable

- Electrostatic resistance

More on PVOH…

At Aquapak we believe that new materials are needed to help replace the conventional plastic that was invented decades ago and continues to pollute our environment today.

We strongly believe in recycling and reusing useful materials, but the recycling system is complex, varies from region to region and is far from perfect. Thousands of tonnes of conventional or ‘hard-to-recycle’ plastic is still shipped around the world before being either incinerated, sent to landfill or worse, ends up floating around in our seas poisoning and endangering wildlife.

Most of this plastic pollution comes from polypropylene (PP) or polyethylene (PE)). These materials were deliberately developed to last a very long time, when sustainability wasn’t a major concern, and as such are highly persistent sometimes taking centuries to degrade because of their chemical stability and resistance to microbial degradation.

In contrast, PVOH offers a significant advantage over these conventional plastics because of its inherent biodegradability.

How long does it take for PVOH to break down?

The speed of break down is always dependent on factors such as temperature, microbial activity, and nutrient availability. However, even during longer degradation processes, PVOH poses less long-term environmental risk than PP and PE, which resist degradation and can persist as microplastics indefinitely.

PVOH it is also less likely to contribute to the widespread, long-lasting pollution caused by more durable plastics.

In comparison, PP and PE not only absorb persistent pollutants like PCBs and DDT, but also contribute to the accumulation of marine debris, where their buoyancy leads to widespread distribution across marine environments. This can cause significant physical harm to wildlife through ingestion and entanglement. PVOH, on the other hand, is water-soluble and hydrophilic, which reduces its physical impact on marine life.

PVOH has its limitations but is an excellent starting point for the development of a new materials like Hydropol™ that can move us closer to eliminating persistent plastic pollution. Until we invent the perfect solution to the plastic crisis, Hydropol™ helps us progress toward significantly less harmful plastic waste.

By transforming the thermal processing properties of PVOH, Hydropol™ unlocks a wealth of possibilities for better packaging solutions that alongside improved recycling technologies and a more resource-efficient circular economy can begin to mitigate the lasting damage caused by traditional plastics.