Table of Contents

Biodegradable Polybags for Fashion: Protecting Products Without Harming the Planet

Every year, billions of polybags are used across the global fashion industry to protect garments during transport and storage. Traditionally made from LDPE plastic, these bags are durable but rarely recycled — often ending up in landfill or polluting rivers and oceans.

With growing consumer demand and tightening legislation, brands need alternatives that combine performance with sustainability. Thanks to recent pioneering developments in polymer and materials science biodegradable polybags that are also marine-safe are now a viable solution, designed to keep products safe while offering genuine end-of-life responsibility.

Why Fashion Needs Biodegradable Polybags

Polybags are essential for protecting garments from moisture, dirt and damage, particularly across complex global supply chains. However, the fashion sector is under increasing pressure to reduce plastic waste.

- Conventional plastic bags last hundreds of years.

- Recycled polybags only delay the problem — and often use energy-intensive processes.

- Retailers and brands have committed to making all packaging recyclable, compostable, or biodegradable by 2025–2030.

Biodegradable polybags for fashion provide a scalable solution, aligning with both regulatory changes and consumer expectations. The scale of polybag use in global fashion logistics is huge — but solutions are emerging. For example, Aquapak has outlined fashion’s polybag solution to help the industry move away from single-use hard-to-recycle flexible plastic that pollute the environment for decades.

What Are Biodegradable Polybags?

Biodegradable polybags are protective garment bags made from innovative polymer technology such as Hydropol™. Unlike standard plastics, Hydropol™ is:

- Water-soluble – it dissolves safely in recycling processes or water.

- Marine-safe – if it escapes into the environment, it biodegrades without creating harmful microplastics. This is especially important given that British shoppers are most concerned about harmful microplastics from plastic packaging.

- Durable – offering the strength, clarity and barrier properties fashion brands rely on.

This combination means fashion brands no longer need to compromise between functionality and sustainability.

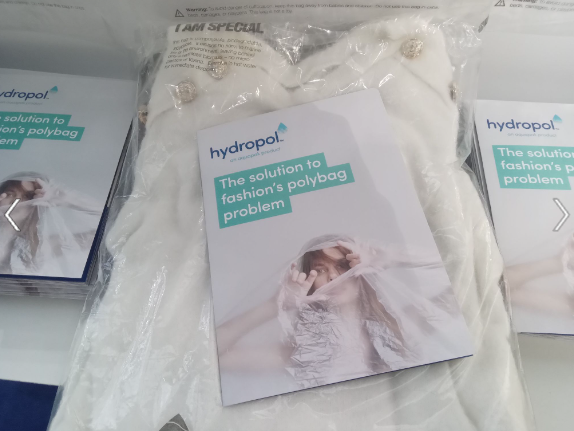

Try it for your self!

Research shows that fashion retailers and brands are exploring sustainable packaging, but adoption remains inconsistent — making biodegradable garment bags a practical way forward.

By using Hydropol™, brands can adopt sustainable garment bags at scale, without costly changes to existing packaging lines.

End-of-Life Options for Biodegradable Polybags made with Hydropol™

Unlike traditional plastics, Hydropol™ offers multiple environmentally safe disposal routes:

- Recycling – dissolves in paper mill recycling, enabling full fibre recovery.

- Biodegradation – breaks down into CO₂, water and natural biomass, leaving no harmful microplastics.

- Composting – disintegrates in industrial composting conditions.

- Anaerobic Digestion – converts into renewable energy in the form of biogas.

This flexibility ensures fashion brands can meet circular economy goals and future-proof their packaging against upcoming regulations. With regulations tightening, solutions like Hydropol™ are already being aligned with new packaging legislation such as PPWR and EPR schemes to ensure compliance.

Benefits for Large Fashion Brands

Biodegradable polybags for fashion are not just an eco upgrade — they deliver tangible business benefits:

- Meet brand sustainability pledges (e.g., 100% recyclable or biodegradable packaging by 2025/30).

- Enhance consumer trust with credible, science-backed claims (avoiding accusations of greenwashing).

- Maintain performance – garment bags remain strong, clear and protective.

- Scale easily – seamless integration with existing conversion and packing lines.

Fashion Case Studies

Several forward-thinking fashion brands are already making the switch to Hydropol™ biodegradable polybags:

- Finisterre – pioneering marine-safe garment bags to protect knitwear.

- N Brown – the UK’s largest online fashion retailer to adopt Hydropol™ garment bags.

- Zone3 – using sustainable garment bags to reinforce their eco credentials.

These examples demonstrate that biodegradable polybags are not only technically feasible but also commercially scalable for leading fashion brands.

Working with Packaging Convertors

Scaling biodegradable garment bags across global fashion supply chains depends on close collaboration with convertors. Hydropol™ integrates into existing extrusion, lamination and bag-making processes, meaning brands can adopt eco polybags at scale without major investment.

By partnering with convertors already working with Hydropol™, fashion brands can ensure:

- Reliable supply for large volumes.

- Consistency in quality and performance.

- Access to certified sustainable packaging that meets global retailer requirements.

Aquapak works directly with convertors and brand owners through partnerships and collaboration, ensuring smooth technical transfer and reliable supply for large volumes of garment bags. This approach helps fashion brands access certified sustainable packaging that meets both performance and environmental goals.

The fashion industry faces an urgent need to replace conventional polybags with biodegradable, sustainable alternatives. Hydropol™ polybags offer the strength and clarity brands require, with the environmental responsibility consumers demand.

The future of fashion packaging is here — and it’s time to see it for yourself.

Request a fashion sample pack and watch the polybags dissolve in water.